1. Birth of an Idea:

The Conceptual Foundations (1960s-1980s):The seeds of 3D printing were sown in the 1960s when inventors and scientists began exploring the idea of layer-by-layer fabrication. Early pioneers such as Charles Hull and Hideo Kodama laid the groundwork for what would become additive manufacturing. Hull's patent for "stereolithography" in 1986 marked a pivotal moment, introducing the concept of using lasers to solidify liquid resin into layered objects.

2. Layer by Layer:

Stereolithography and Selective Laser Sintering (1980s-1990s):The 1980s witnessed the birth of stereolithography apparatus (SLA) and the commercialization of the technology by Hull, leading to the formation of 3D Systems Corporation. Concurrently, selective laser sintering (SLS) emerged, allowing for the sintering of powdered materials into solid forms. These foundational techniques paved the way for additive manufacturing, gradually gaining attention across industries.

3. From Prototyping to Production:

Advancements and Applications (2000s):The turn of the millennium brought advancements in materials, precision, and accessibility. 3D printing evolved from a prototyping tool to a viable method for producing functional parts. Industries such as aerospace, automotive, and healthcare began integrating 3D printing into their manufacturing processes, showcasing its potential to revolutionize design, production, and customization.

4. The Rise of Desktop 3D Printing and Open Source (2010s):

The democratization of 3D printing gained momentum in the 2010s with the introduction of affordable desktop 3D printers. Open-source initiatives, like the RepRap project, fostered a community-driven approach, enabling enthusiasts to build and modify their own machines. This era saw a surge in creativity, as makers, hobbyists, and educators harnessed 3D printing for artistic, functional, and educational purposes.5. Industrialization and Cutting-Edge Applications (2010s-2020s):

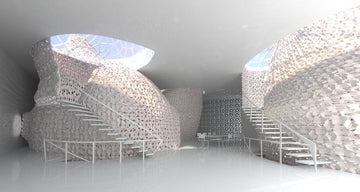

In tandem with the growth of consumer 3D printing, industrial-grade machines emerged with enhanced capabilities, such as multi-material printing, large-scale production, and advanced metal additive manufacturing. Industries embraced 3D printing for intricate aerospace components, medical implants, architectural prototypes, and even food. The technology's potential to disrupt supply chains and enable on-demand manufacturing became increasingly evident.

6. Beyond Imagination:

Current and Future Possibilities (2020s and Beyond):

As we step into the current decade, 3D printing continues to push boundaries. The technology is advancing rapidly in terms of materials, speed, and scale. Bioprinting is making strides in tissue engineering and organ transplantation, while 3D-printed electronics merge physical form with functional circuits. With ongoing research and innovation, the possibilities for 3D printing seem boundless, heralding a future where complexity and customization converge seamlessly.

Conclusion:

The journey of 3D printing from its conceptual roots to its current state is a testament to human innovation and adaptability. From the pioneering efforts of visionaries to the democratization of technology, 3D printing has transformed industries, inspired creativity, and paved the way for a future where the digital and physical realms harmoniously intersect. As we look ahead, the evolution of 3D printing continues to captivate our imagination, promising a future where the boundaries of design, manufacturing, and innovation are redefined.