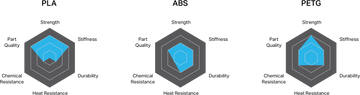

Understanding the differences between popular 3D printing filaments, namely PLA, ABS, and PETG, is essential for achieving successful prints and selecting the best material for specific applications. Each filament has unique characteristics, strengths, and weaknesses that make them suitable for different use cases. Let's explore the key differences and their best applications:

PLA (Polylactic Acid):

Characteristics: PLA is a biodegradable and environmentally-friendly filament made from renewable resources like cornstarch or sugarcane. It is non-toxic and emits a pleasant sweet smell while printing. PLA is available in various colors and has a glossy or matte finish depending on the specific type.

Best Applications: PLA is ideal for beginners and hobbyists due to its ease of use and minimal warping. It is suitable for creating decorative items, prototypes, and objects that do not require high-temperature resistance or mechanical strength. PLA is commonly used for artistic projects, educational models, and household items.

Notable Considerations: PLA can be brittle and is not recommended for functional parts subjected to heavy stress or outdoor use, as it may degrade over time when exposed to sunlight and moisture.

ABS (Acrylonitrile Butadiene Styrene):

Characteristics: ABS is a durable and impact-resistant filament, making it suitable for functional parts and engineering applications. It has higher temperature resistance than PLA and exhibits less shrinkage during cooling, reducing warping issues.

Best Applications: ABS is commonly used for functional prototypes, mechanical parts, and items that require heat resistance, such as automotive components, enclosures, and electronics housings.

Notable Considerations: ABS emits a noticeable odor during printing, and adequate ventilation is essential. It also requires a heated build plate to minimize warping. Due to its higher printing temperature, ABS may not be as beginner-friendly as PLA.

PETG (Polyethylene Terephthalate Glycol-Modified):

Characteristics: PETG is a versatile filament that combines the ease of printing of PLA with the durability of ABS. It has excellent layer adhesion, low warping, and higher temperature resistance.

Best Applications: PETG is suitable for a wide range of applications, including functional parts, mechanical components, and containers. It is commonly used for food-safe items, water bottles, and storage containers due to its non-toxic and BPA-free nature.

Notable Considerations: PETG may require a heated build plate for better adhesion and can be more challenging to print than PLA. However, it is generally more forgiving than ABS in terms of warping and shrinkage.

Choosing the right filament material is essential for achieving successful 3D prints that meet the specific requirements of your projects. PLA is excellent for beginners and decorative items, while ABS is ideal for functional parts and engineering applications with higher temperature demands. PETG strikes a balance between the ease of printing and durability, making it suitable for a wide range of use cases, including food-safe and functional items. Understanding the characteristics and best applications of each filament material will empower you to make informed decisions and unleash the full potential of your 3D printing projects.